Removal of NOx and SOx from recovery boilers using ClO2 De-NOx technology

A global challenge

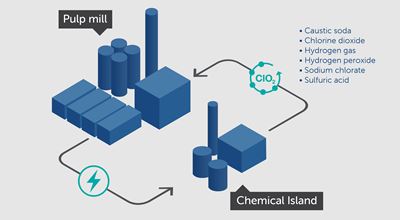

Chlorine dioxide(ClO2), produced from sodium chlorate, is a powerful solution that can be used in De-NOx technologies abating NOx and SOx emissions in the pulp and paper industry.

Combustion of fuels creates emissions of nitrogen oxides (NOx) and sulfur dioxides (SOx) which are associated with adverse effects on human health and causing environmental problems. These harmful emissions are considered a global concern worldwide and stricter legislation and regulations are continually being implemented.

We offer the next generation’s ClO2 based De-NOx technology for improved emission control systems for all industries, including the pulp and paper industry.